Cleanroom experts

Engineering services

Engineering services are essential to design, plan and optimize the technical aspects of any project.

Through them, we bring great value to the process by ensuring efficient and customized solutions that meet your specific needs and requirements.

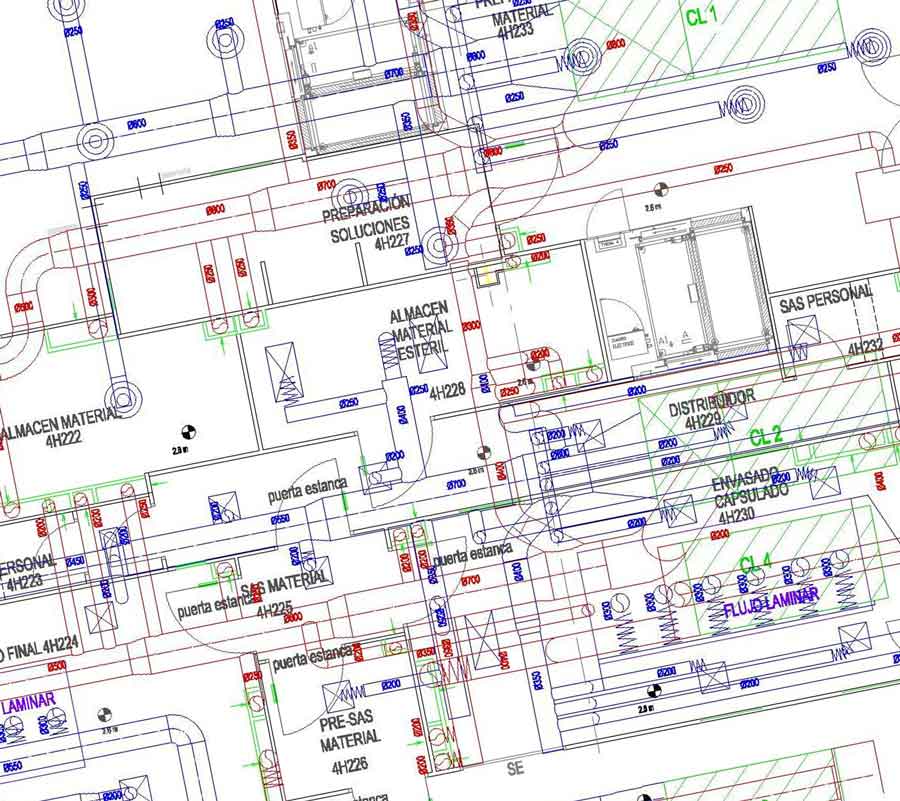

Integral architectural projects FOR CLEAN ROOMS

Engineering Projects

At Iguña, we provide customized engineering solutions tailored to the needs, spaces and regulations of each client and industry.

Our projects cover three levels: conceptual, basic and detailed, guaranteeing a comprehensive approach tailored to your specific requirements.

Concept project

Feasibility Study and Requirements

Our Conceptual Project service offers an evaluation of the economic, technical and legal feasibility of a potential investment.

This analysis serves to elaborate the user requirements of the project together with the client, setting the basis and guidelines for the basic and detailed engineering, as well as the execution deadlines.

Basic project

Integral Design and 3D Modeling

The Basic Project starts with the feasibility study, allowing us to design and develop a global vision of the project through 3D BIM (Building Information Modelling) models.

This approach centralizes all information and facilitates decision making during the cleanroom design and construction process.

Detail project

Detailed Project and Quality Validation

In the Detailed Design, we start with the basic engineering and perform the calculations and quality validations required for the subsequent elaboration of all the construction details of the project.

Once validated by the property, the detailed projects become executable, guaranteeing compliance with the regulations and standards applicable in each case.

Clean rooms and modular classified spaces

Pharmaceutical construction

We design and execute the construction and installation of clean rooms and classified spaces complying with the strictest requirements of the UNE-EN ISO 14644, FDA and GMP standards.

As a manufacturer, we develop and produce our own innovative solutions tailored to the needs of any type of project.

When carrying out the execution, we provide you with a team specialized in the installation of rooms that guarantees the shortest possible lead times, the greatest technical knowledge and the highest level of quality.

In addition, and thanks to the advantages of the integrated, modular and tailor-made system of MCPMCP, consisting of panels, doors, viewers, lights, protections, material pass-throughs and profiles, we can install quickly, without cuts or waste on site, without waste and with a perfect finish.

Controlled environment according to GMP and UNE-EN ISO 14644

HVAC installations

Iguña develops HVAC systems (Heating, Ventilation and Air Conditioning) systems for clean rooms in compliance with GMP and UNE-EN ISO 14644 standards, guaranteeing adequate environmental parameters in terms of particles, temperature and humidity.

We design and size air handling systems, including air handling units (AHUs), temperature and humidity control air handling units (AHUs), temperature and humidity regulation, distribution and filtration. Our specialized team is in charge of the installation and follow-up of the work.

In addition, to complete the installation and under the Kirhtech brand name, we offer auxiliary equipment to improve environmental control and protection in critical operations: laminar flows, air showers, RABS (Restricted Access Barrier Systems) and material pass-throughs.We also offer auxiliary equipment to improve environmental control and protection in critical operations: laminar flows, air showers, RABS (Restricted Access Barrier Systems) and material pass-throughs.

All of this equipment can be tailor-made according to the needs of the project.

ADVANCED management of critical environments

Regulation and control

Implementation of advanced control and supervision systems in critical environments.

Iguña programs and installs architectures for Regulation and Control in Classified Areas, complying with GMP and FDA CFR21 part 11 regulations, ensuring compliance with UNE-EN ISO 14644 in the control of critical parameters. control of critical parameters.

We centralize and program all the information of the room by means of PLC.We adapt to the customer’s needs by offering the possibility of integrating analog or digital elements in the control system. For remote control and monitoring of data, we connect the PLC to SCADA systems.

Iguña uses the latest technology, allowing automatic controls of room data in real time and guaranteeing optimal conditions. In addition, we perform quality audits and preventive maintenance to ensure the proper functioning of our control systems.

Efficient and scalable electrification

Electrical installation

Design and development of efficient and sustainable electrical systems for controlled environments.

Iguña offers solutions in the study and development of electrical installations for clean rooms, complying with the European Low Voltage Directive (EC) and the UNE-EN ISO 14644 standard for lighting. We carry out lighting and consumption studies to ensure sustainable and efficient energy use.

In the design of the electrical installations, we evaluated the power demanded by the room, developing general panels, control subpanels and power distribution to all the elements.

Our experience ensures optimal electrical solutions tailored to the specific needs of each project in cleanroom environments.

WATER, STEAM and OTHER GASES

Critical fluids

Iguña offers integral solutions in design and installation of critical fluids, gases and compressed air systems in clean rooms, complying with GMP, Ph.Eur and USP regulations.

We evaluate whether it is necessary to implement a Water For Injection (WFI), a Purified Water System (PW/HPW) or a Pure Steam System, adapting to the specific needs of each activity.

We take care of planning and adapting the installation of critical fluids in clean rooms, including the location of storage systems, distribution lines, flow control and filtration stages.

During execution, we provide a specialized team to manage the work and coordinate follow-up with the property.